Coreline’s New Trenchless Pipe Lining Process: UV-Cured CIPP

Trenchless pipelining is the process of rehabilitating old pipes without having to dig them up. The video on this page explains the process from start to finish.

A damaged pipe is a major problem and can come with major expense. Cured-in-place pipe (CIPP) offers an alternative to destructive excavation and expensive pipe replacement, and at Coreline, we offer the very latest in CIPP repair.

our new resin-based trenchless pipe repair process: UV-cured CIPP

The typical trenchless pipe repair process is, without a doubt, more efficient than conventional trench repair, but it isn’t perfect. Epoxy-based, water-curing process for lining pipes requires gallons of hot water and hours of curing time. But Coreline’s new resin-based process uses an ultraviolet curing method that saves water, eliminates the need for epoxy, and produces a functioning pipe in mere minutes. Here’s how our UV-Cured CIPP repair works:

1. Liner Preparation

Once an assessment of the damaged pipe is completed, the pipe liner and bladder are cut to length for the repair. The resin is then weighed and integrated into the liner. Once the integration process is done, any excess resin is saved for use in future repairs.

2. Liner Inversion

The liner is then attached to the inversion machine, which uses compressed air to push the liner through the pipe. The liner is blown inside out, positioning the resin between the pipe and the liner. As the bladder continues to inflate inside the inverted liner, the resin is pressed firmly against the walls of the original pipe, perfectly conforming to its shape, including any angles or bends.

3. Liner Hardening

To harden and cure the resin, a powerful UV light reacts with the resin as it is pulled through the pipe. The resin cures in a matter of seconds, saving hours of wait time compared to water-curing systems, and days of repair time compared to conventional pipe repair methods. Within minutes, the new resin pipe is fully hardened, structurally sound, and perfectly molded to the old pipe’s form.

4. Pipe Finalization

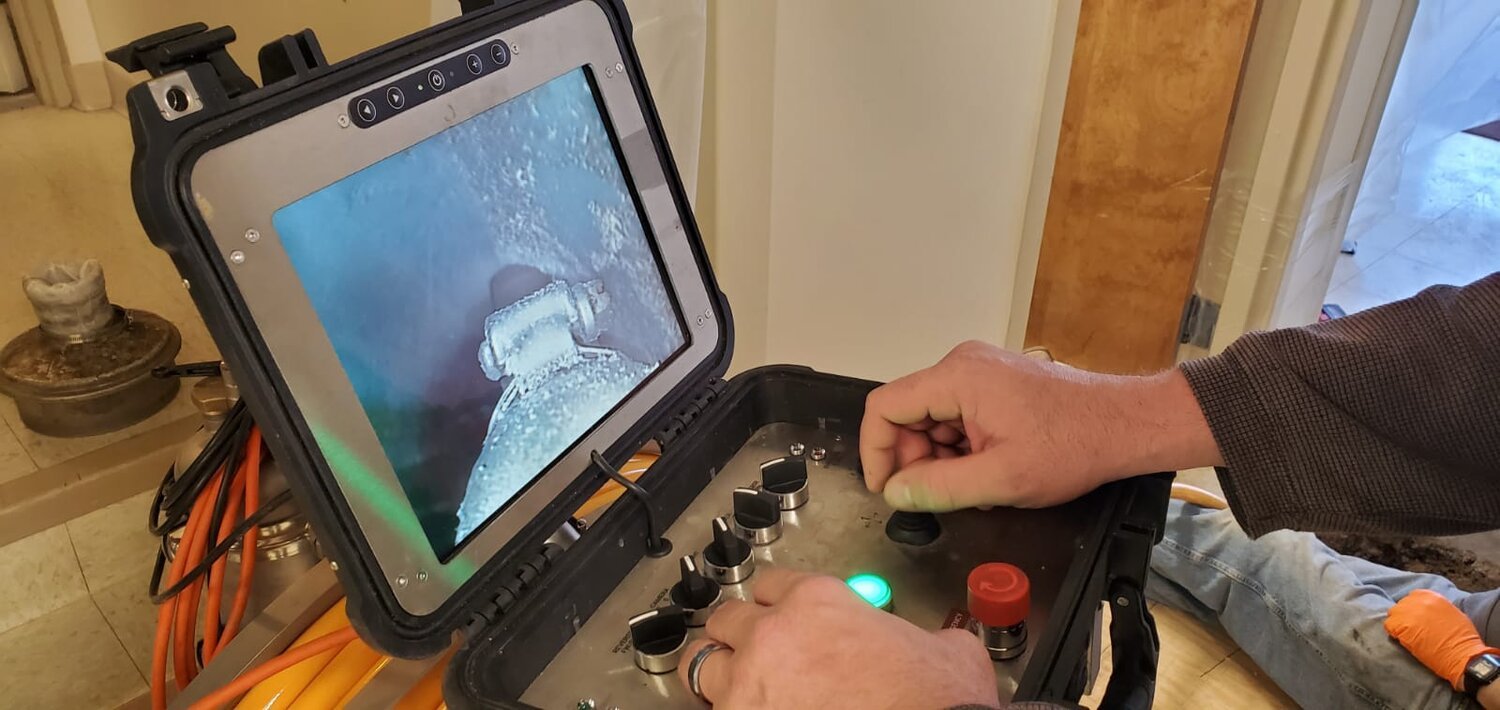

Once the curing process is complete, the inversion bladder is removed. The new pipe is then inspected and declared operational. The final step of the trenchless pipe repair is to cut out any joint intersections with a specialized tool so that the plumbing system can continue to function properly.

FAQs About Trenchless Pipe Lining

-

The process of rehabilitating pipes using relining was invented in England over 30 years ago. Pipe Lining Plus innovative systems and materials have been utilized to install over 8 million feet of relined pipe worldwide.

-

Yes! Most pipe systems only require 20% of their integrity to begin the trenchless pipe lining process. If drainage pipes have not completely collapsed, in most cases, we can rehabilitate the pipe back to a functional drainage line. A pipe lining specialist will perform a full on-site inspection to first assess the condition of the piping system, the nature of the problem, and advise you as to the best method of restoration.

Get a Free Quote

For a free, no-hassle consultation, fill out the form below and we will get back to you as soon as possible. Or you can give us a call at (877) 747-3247